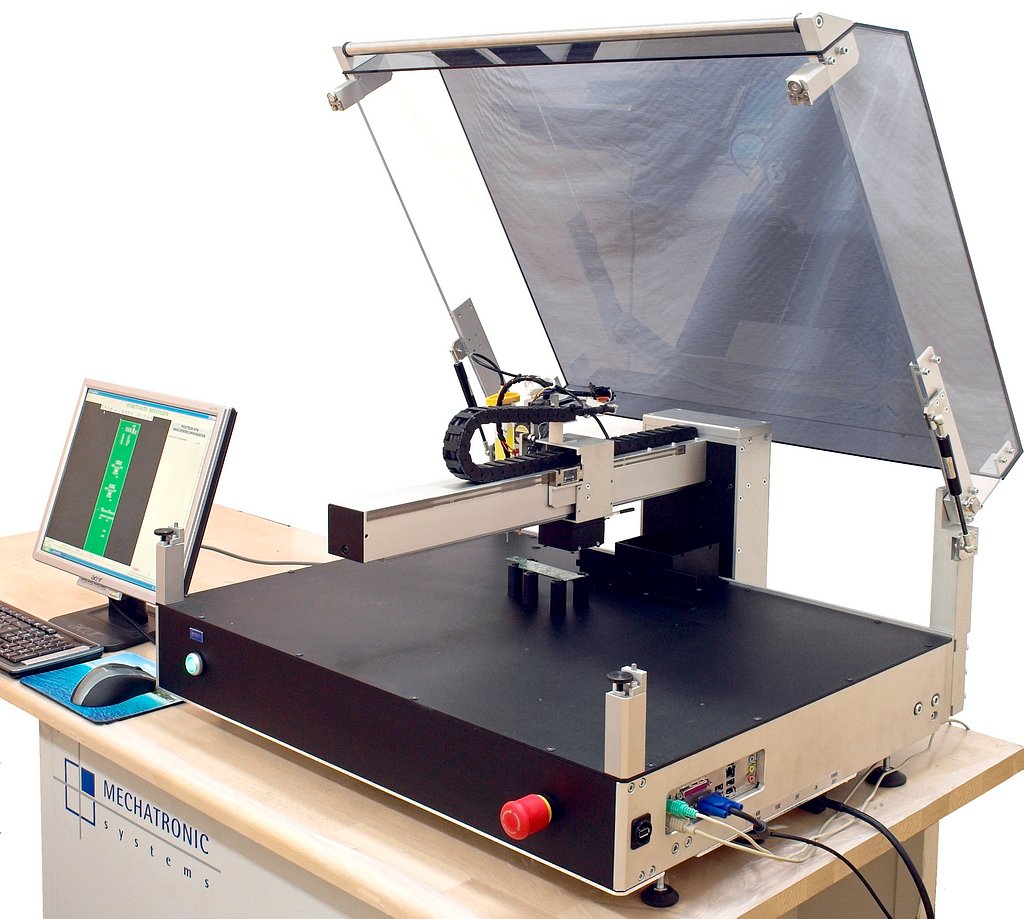

Precision Dispensing with Automated Vision and Needle Calibration

The D10 is a high-performance automatic dispensing machine designed for precision and repeatability. Featuring optical calibration of the dispensing needle in the XY axis, automatic height and length measurement, and a camera system for fiducial detection, the D10 ensures accurate results in even the most demanding applications. With Windows 10 control and an intuitive CAD-based editor, creating and managing dispensing programs is seamless and efficient.