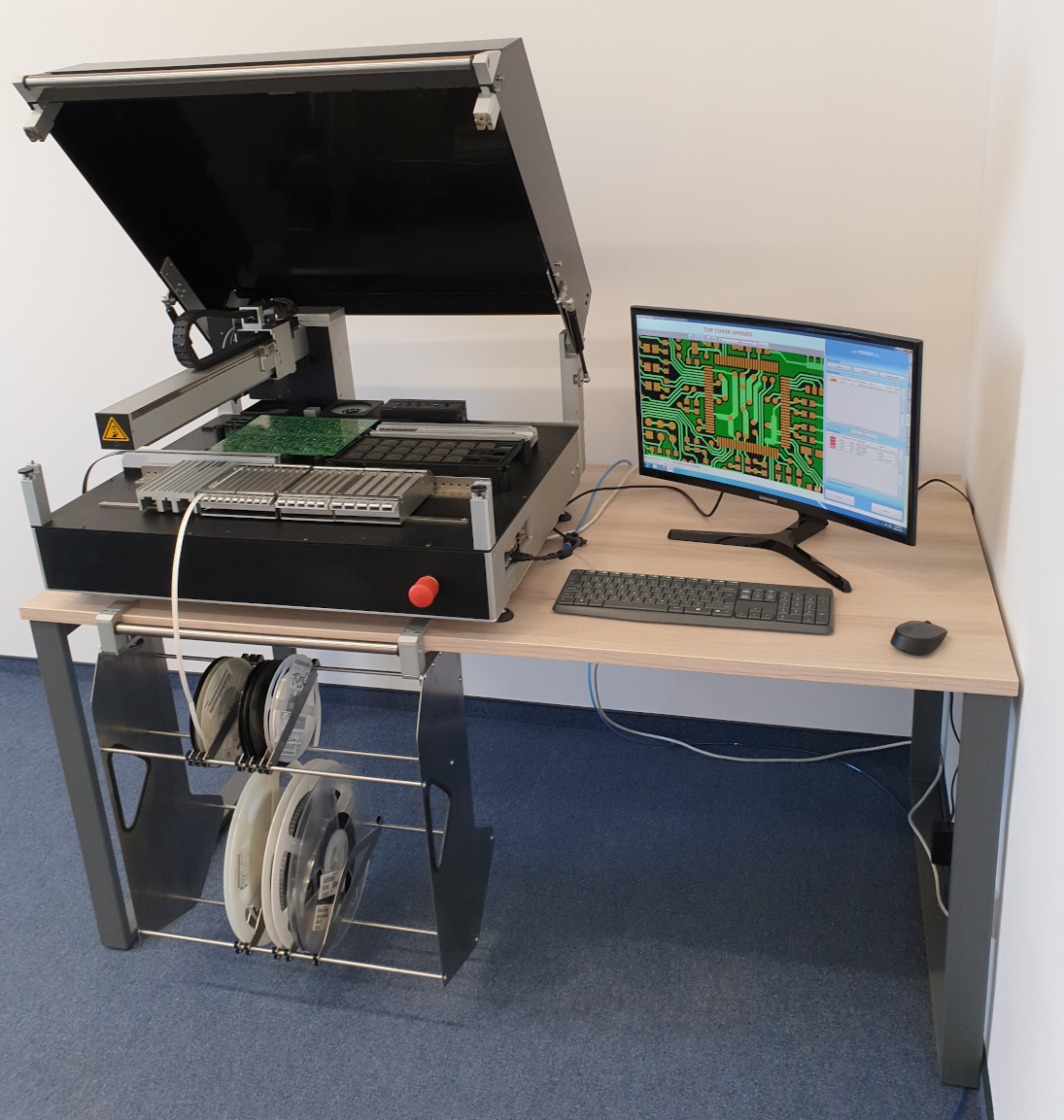

Automatic Pick and Place Solution for Prototyping and Small-Batch Production

The P1 is a compact and highly accurate automatic pick and place machine, ideal for prototyping and small to medium production runs. Supporting a large working area of 540 × 480 mm, it handles a wide range of SMD components from 0201 to 40 × 80 mm, with minimum pitch of 0.4 mm.

With placement rates of up to 1200 components per hour and non-contact component alignment, the P1 delivers fast and reliable operation. High-resolution linear and rotary encoders ensure positioning accuracy of ±0.03 mm. The machine supports tapes, trays, sticks, and bulk packaging, and is designed to work with up to 80 tape feeders and dual IC trays.

Powered by a stable mechanical frame and intelligent control software, the P1 is the perfect choice for labs, startups, and low-volume SMT manufacturers.