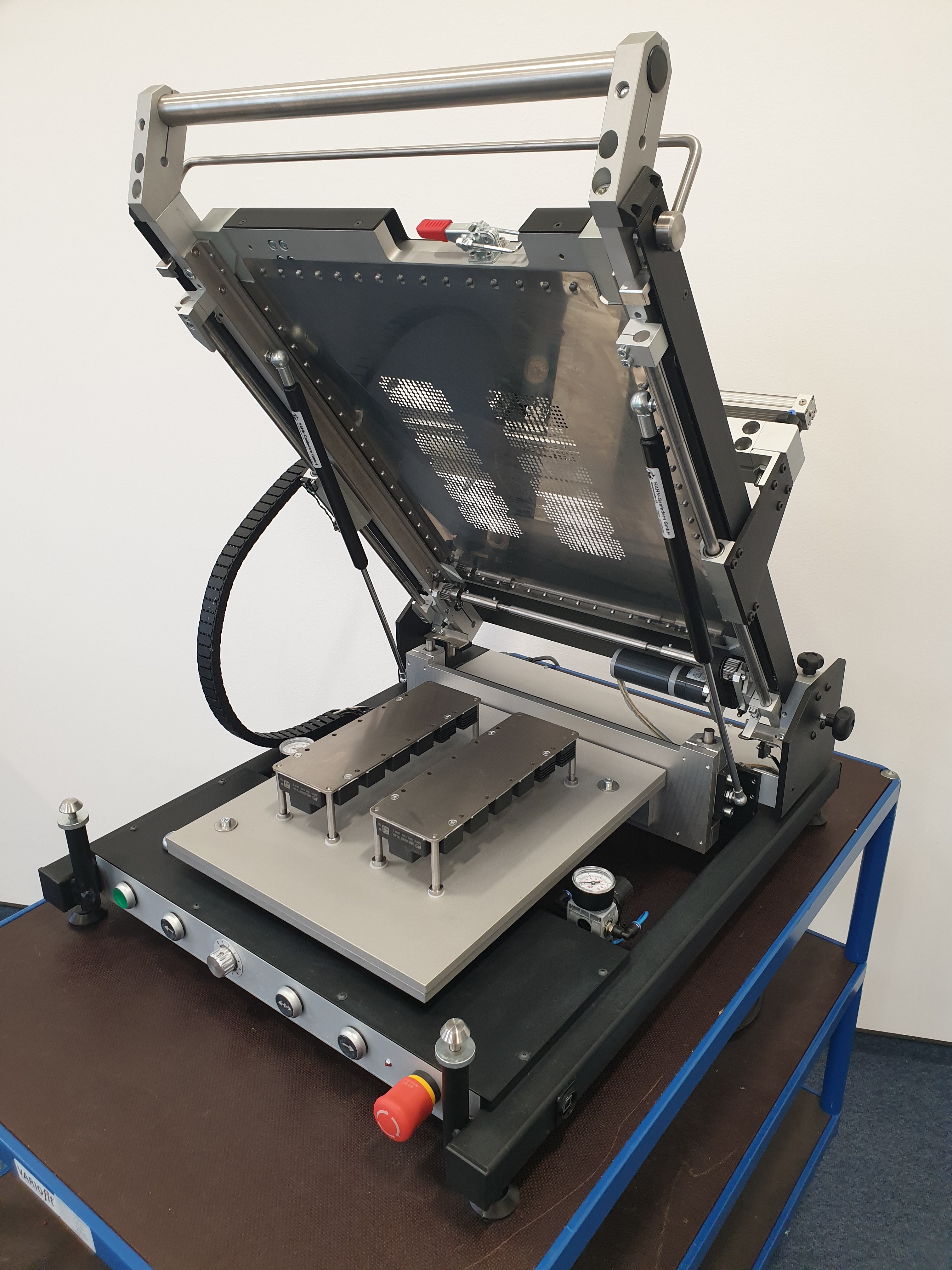

Autodrive - Semi-Automatic SMD Printer S40 with vision system

The S40 stencil printer is a semi-automatic precision screen and stencil printer designed for the highest demands in print quality. The S40 is designed for printing solder pastes, SMD adhesives, or thermal pastes. It can be used as both a screen printer and a stencil printer. The parameterization and automation of all relevant factors that determine print quality is the main advantage of the S40. The printer is therefore designed for small to medium production runs.

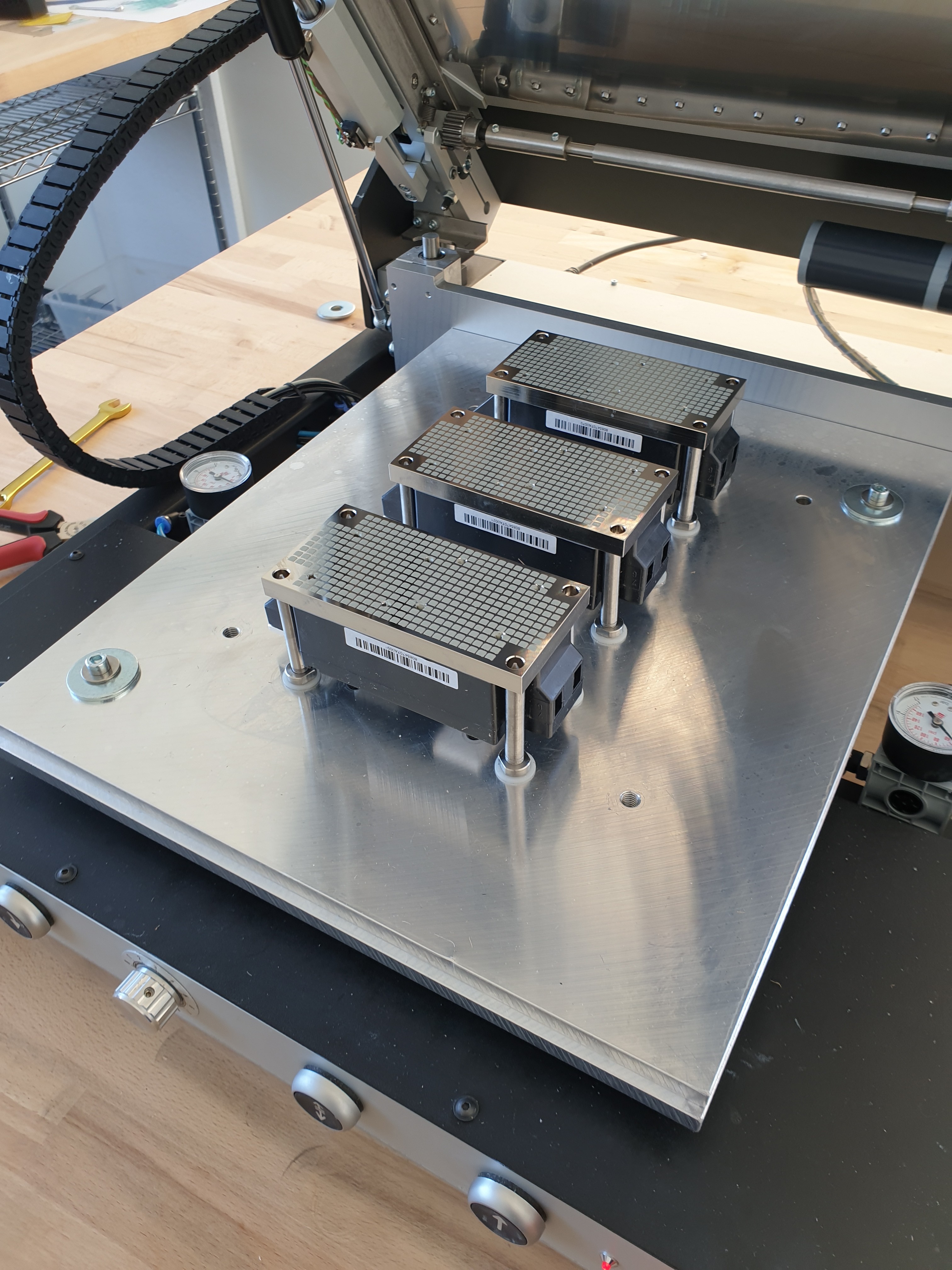

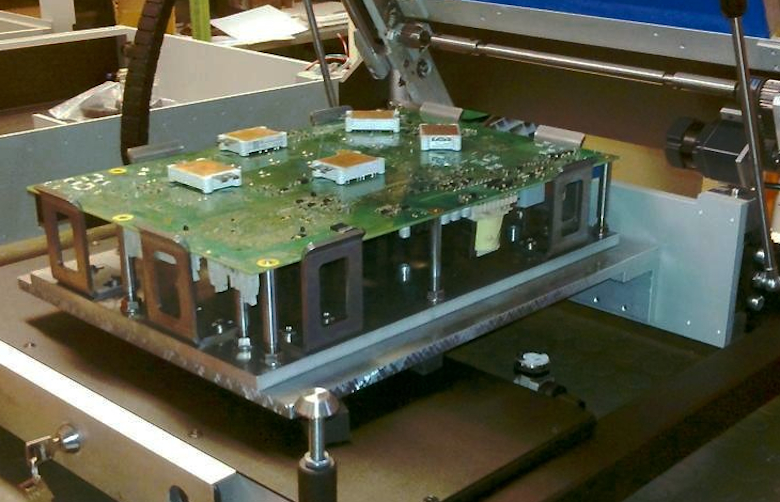

Like all other printers from Mechatronic, the S40 comes standard with a quick-release frame. Quick-release frames from other manufacturers, double-sided clamping systems for older stencils, or fixed frames are also compatible with the S40. The S40 is available as a desktop unit or with a stand. The S40 printer can be further enhanced with a range of accessories for special applications, such as printing on flexible PCBs or ceramic substrates, or printing on IGBT modules or power PCBs.